Processing plants for instant coffee

DEVEX is a market leader in the supply of complete solutions for the production of instant coffee. Our plants enable efficient roasting of the green coffee, extraction of the roasted coffee, concentration, clarification and drying of the coffee extract through to instant coffee as a soluble powder or granulate. Whether it is Arabica or Robusta, espresso or cappuccino, with our plants you will meet the taste of your customers.

Far from standard: Best yield with highest quality

Instant coffee is a world of its own, and so are the DEVEX processing plants. Due to the high investment and operating costs, an instant coffee plant is generally only worthwhile from a production volume of around 1,000 tonnes per year. DEVEX therefore offers standard plants with a production capacity of between 1,000 t/a and 12,000 t/a.

If requested, we can integrate coffee roasting into the overall process and recommend the innovative hot air roasters from our sister company, Neuhaus Neotec.

In extraction, DEVEX's unique technology and extractor design ensures maximum (green) yield, which is higher with our plants than with any other manufacturer. As green coffee accounts for more than 80 % of operating costs, this point is of crucial importance for the profitability of the production plant. Thanks to the optimised yield, up to 1000 tonnes of green coffee can be saved on an annual production of 5000 tonnes of instant coffee, for example.

In addition, our unique aroma recovery process ensures that the aromas of the roasted coffee are retained as far as possible - so that instant espresso really does taste like the Italian original! The further process steps of clarification, concentration and drying are planned and designed individually with the customer. Depending on the desired quality of the end product, spray drying or freeze drying can be used for final refinement.

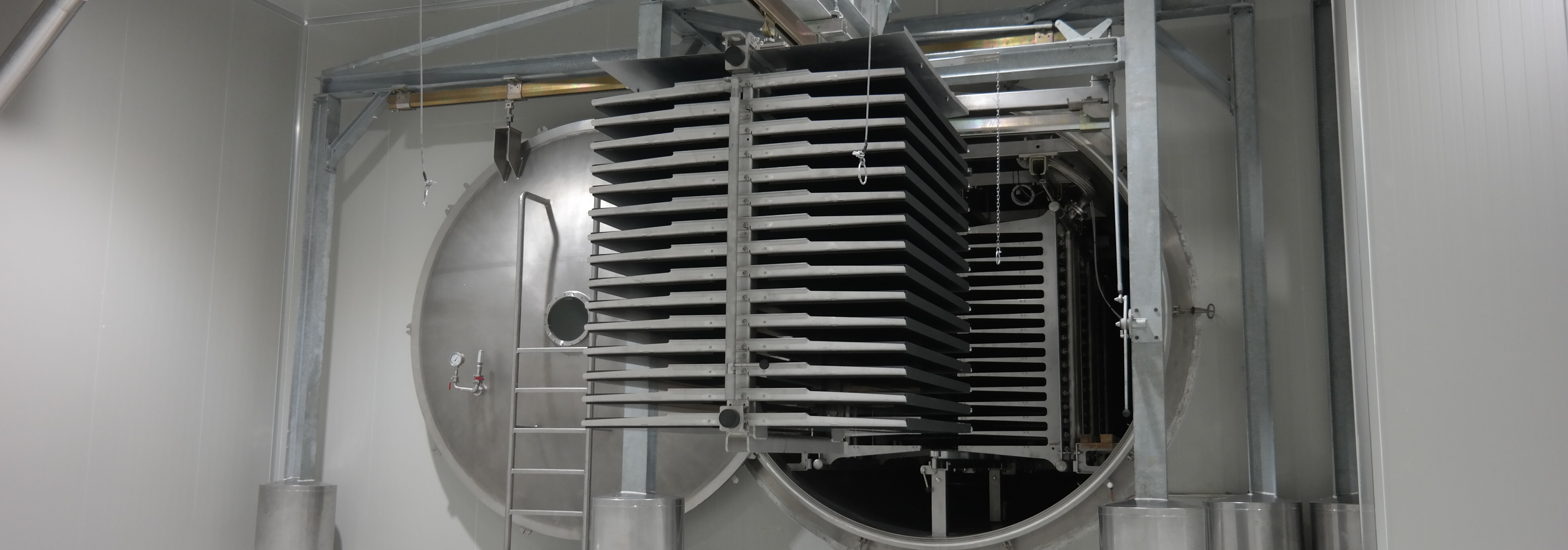

For freeze drying, we offer our own range of DEVEX freeze dryers. For production quantities of < 250 kg/h, batch dryers of type CFD are used and from 250 kg/h to 1000 kg/h our continuous freeze dryers of the CCFD series. Dryers based on this technology have been in use in the industrial sector for many decades.

From foaming to freezing, grinding/screening, drying and bulk filling of the final product, DEVEX offers the complete process chain. For spray drying, however, we work with experienced premium partners.

Another focus of DEVEX plant design is to reduce energy and water consumption in production - all in the interests of sustainable, climate-friendly production! You can save on operating costs and reduce your carbon footprint at the same time! In this context, we are also happy to offer you our DEVEX efficiency advice to optimise your existing plants!

Flexibility is also a hallmark of DEVEX's highly specialised instant coffee plants. We make no distinction between the different types of coffee, nor do we make any difference when it comes to the growing trend of using coffee substitutes based on cereals or chicory. For all aspects of coffee extraction, from small to large scale, DEVEX is your competent partner.